You’ll Find What You Need

We sell to Retail, Trade, DIY and Wholesale customers with discounts for pack lots.

Gippsland Pine – serving Gippsland and beyond since 1993

Gippsland Treated Pine is a family owned and operated Timber & Hardware business with locations in Morwell, Bairnsdale and Beaufort in Victoria, Australia.

We can service areas from Far East Gippsland up into NSW, throughout Gippsland, Western & Northern Victoria and beyond.

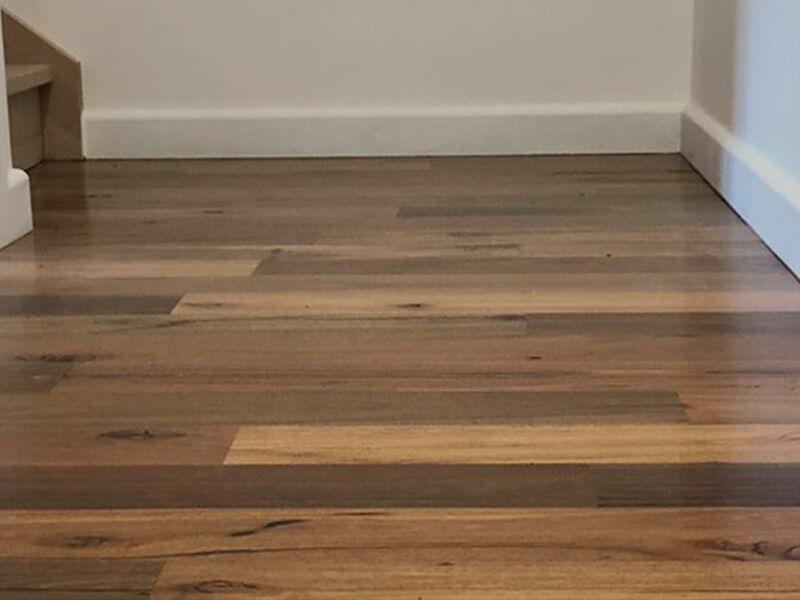

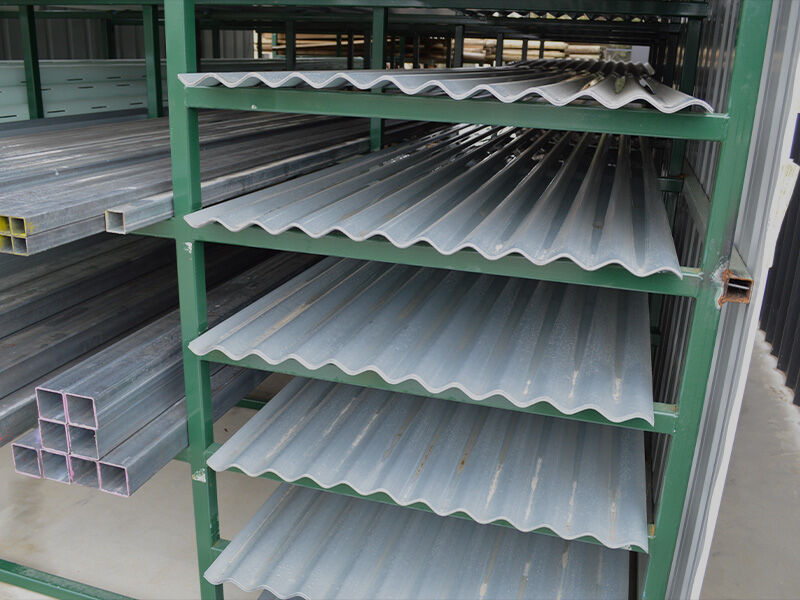

We stock a large range of building timbers, sleepers, decking, palings, rural posts and custom-made morticed post and rail fencing.